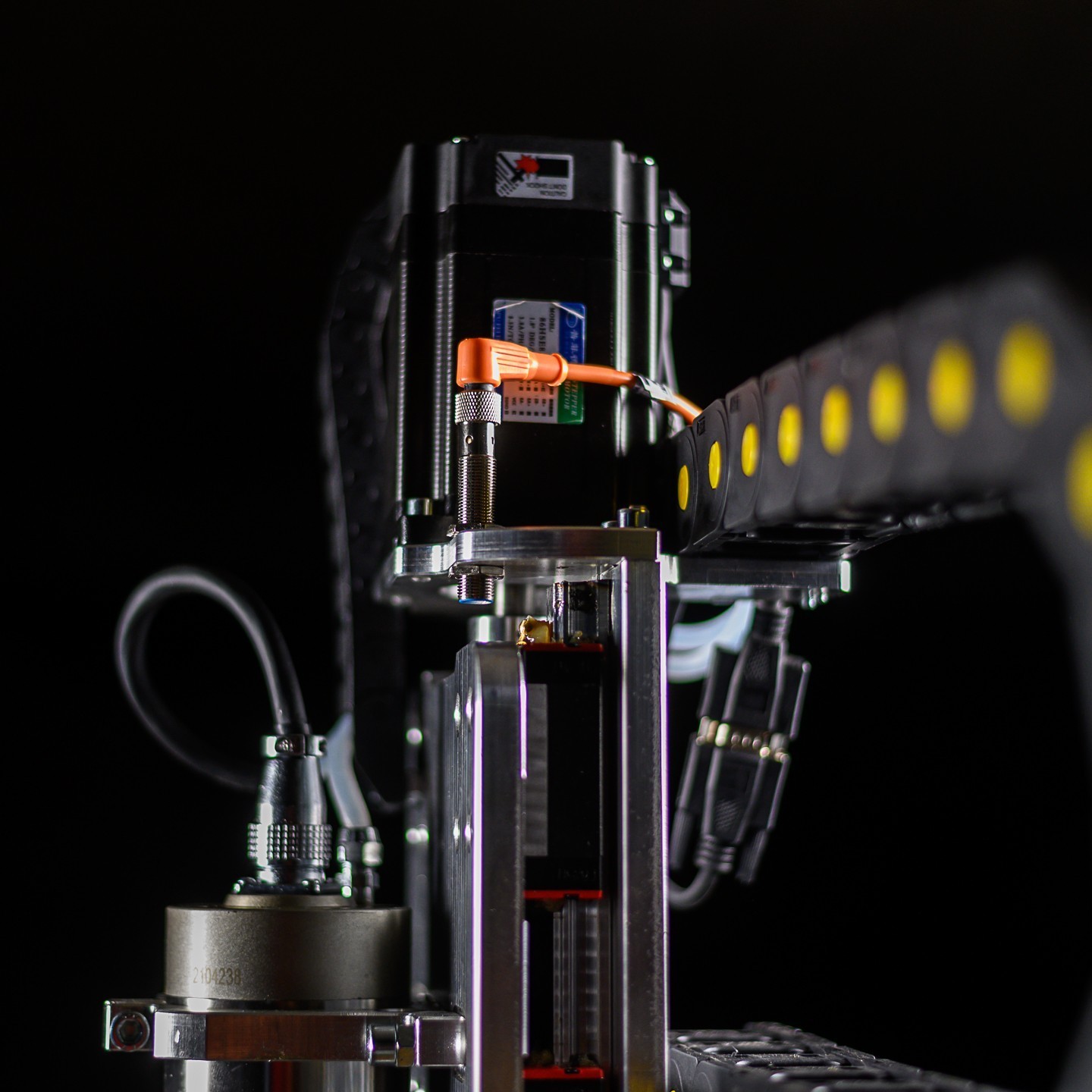

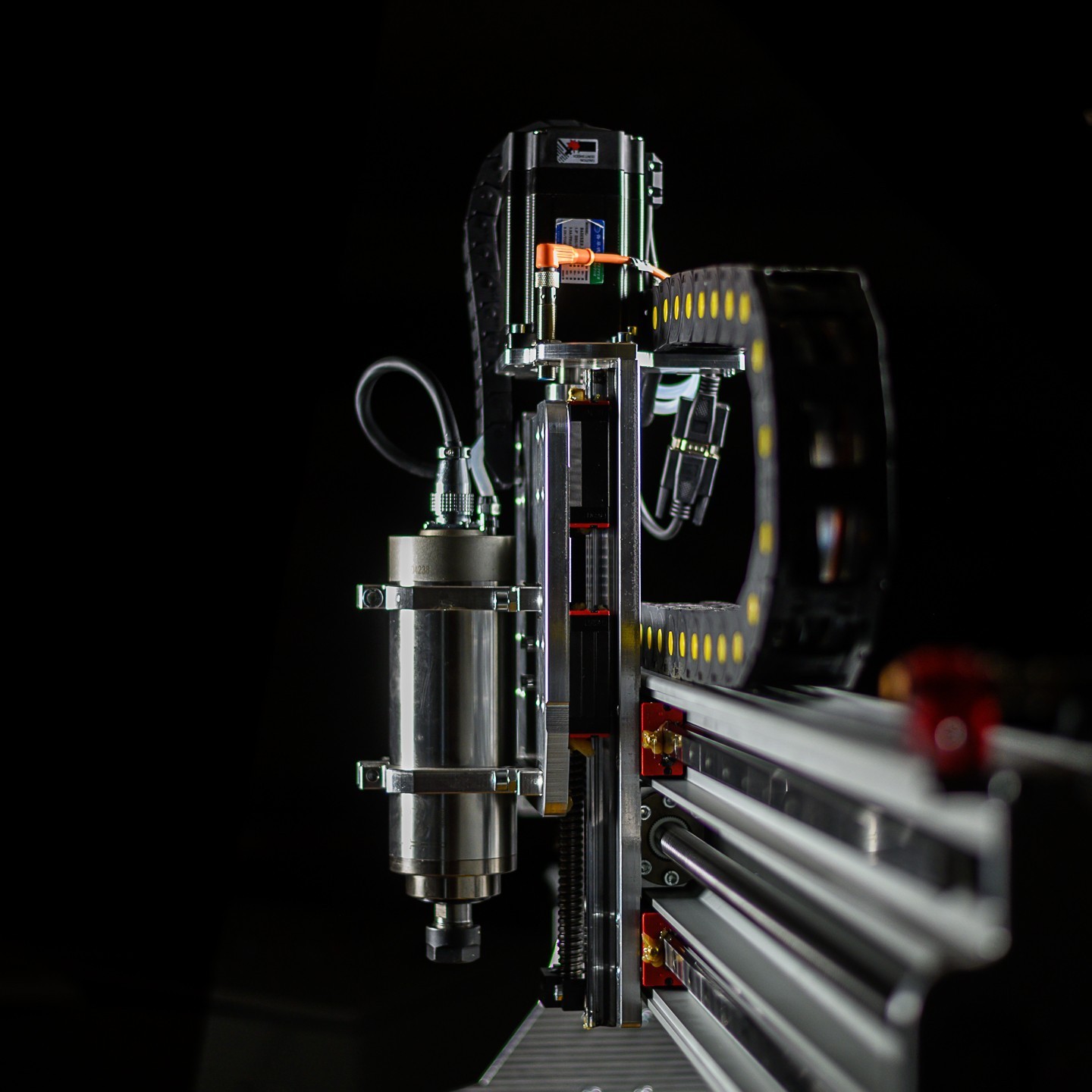

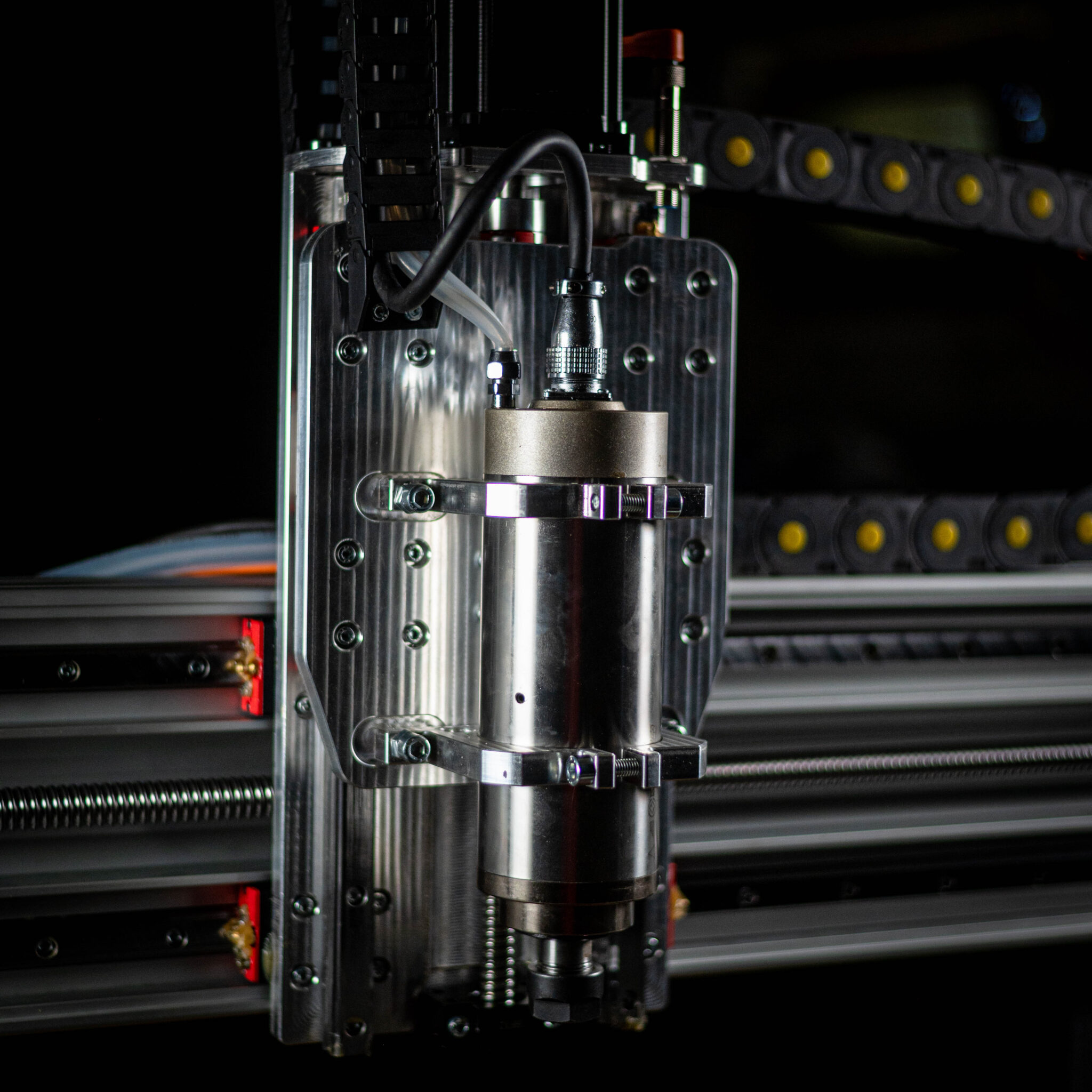

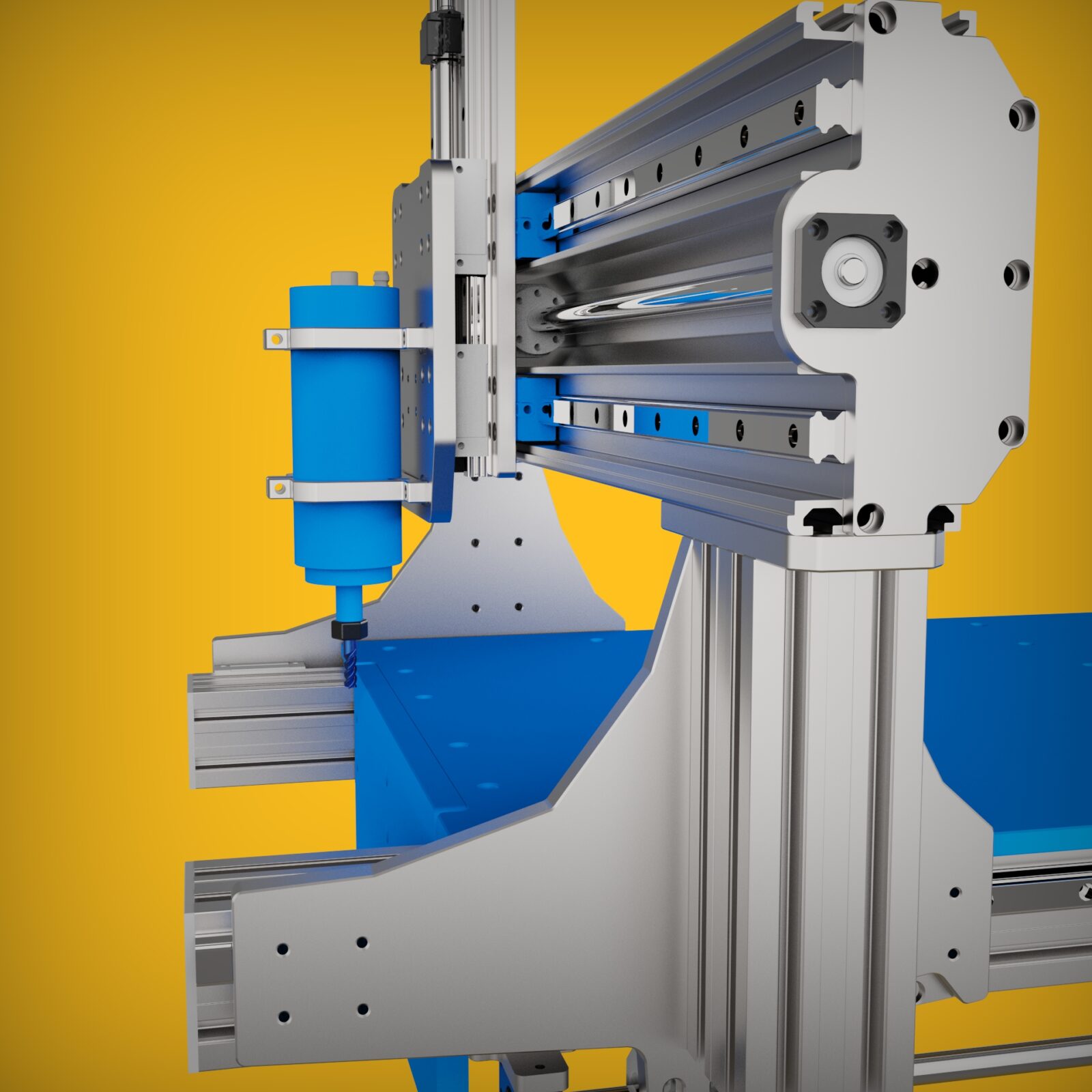

Spindle:

Choose from our selection of air-cooled spindle motors, with power ratings of 1.5 kW, and 2.2 kW. These motors, capable of spinning up to 24000rpm, ensure precision and stability. Paired with a corresponding Inverter VFD, these motors facilitate efficient power conversion and control.

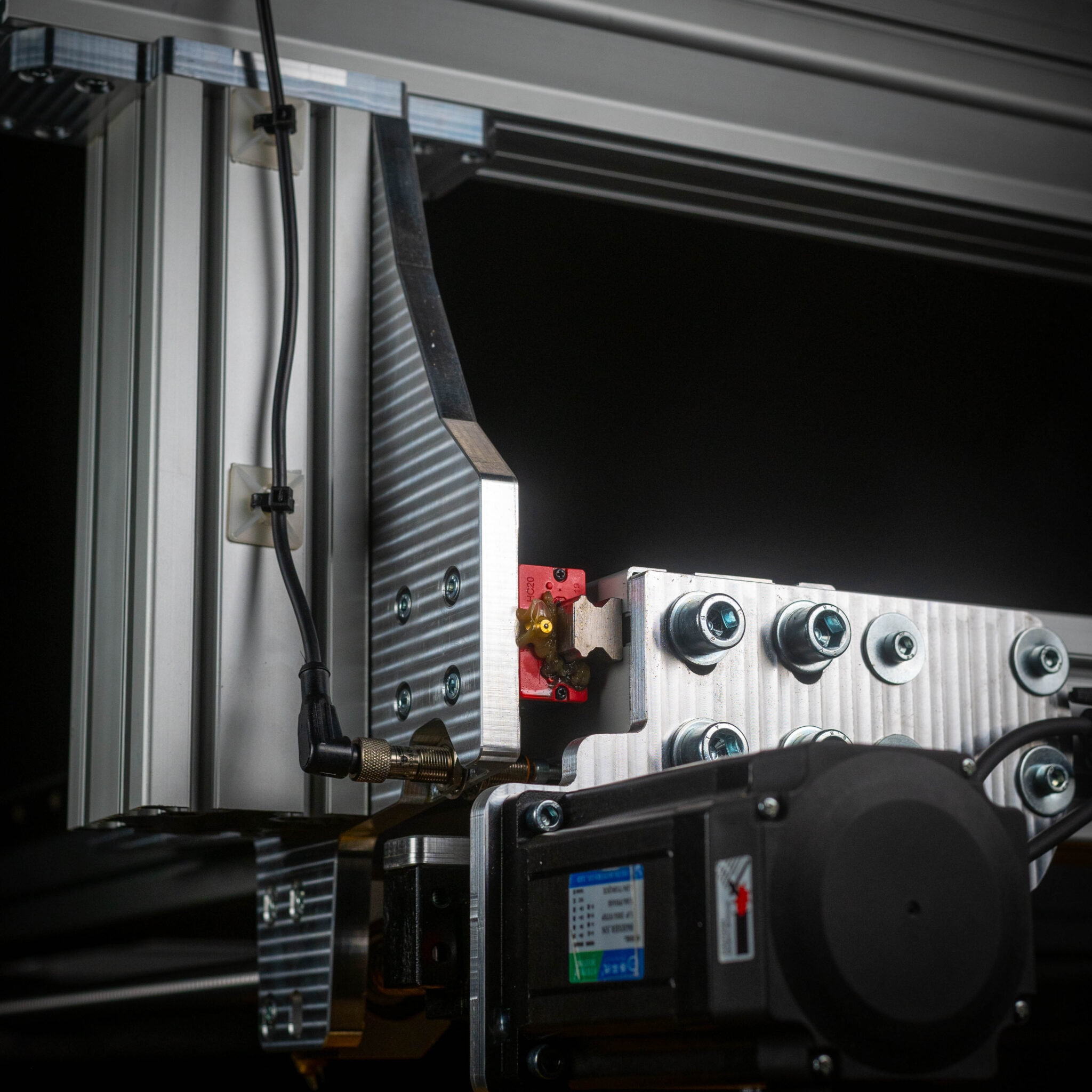

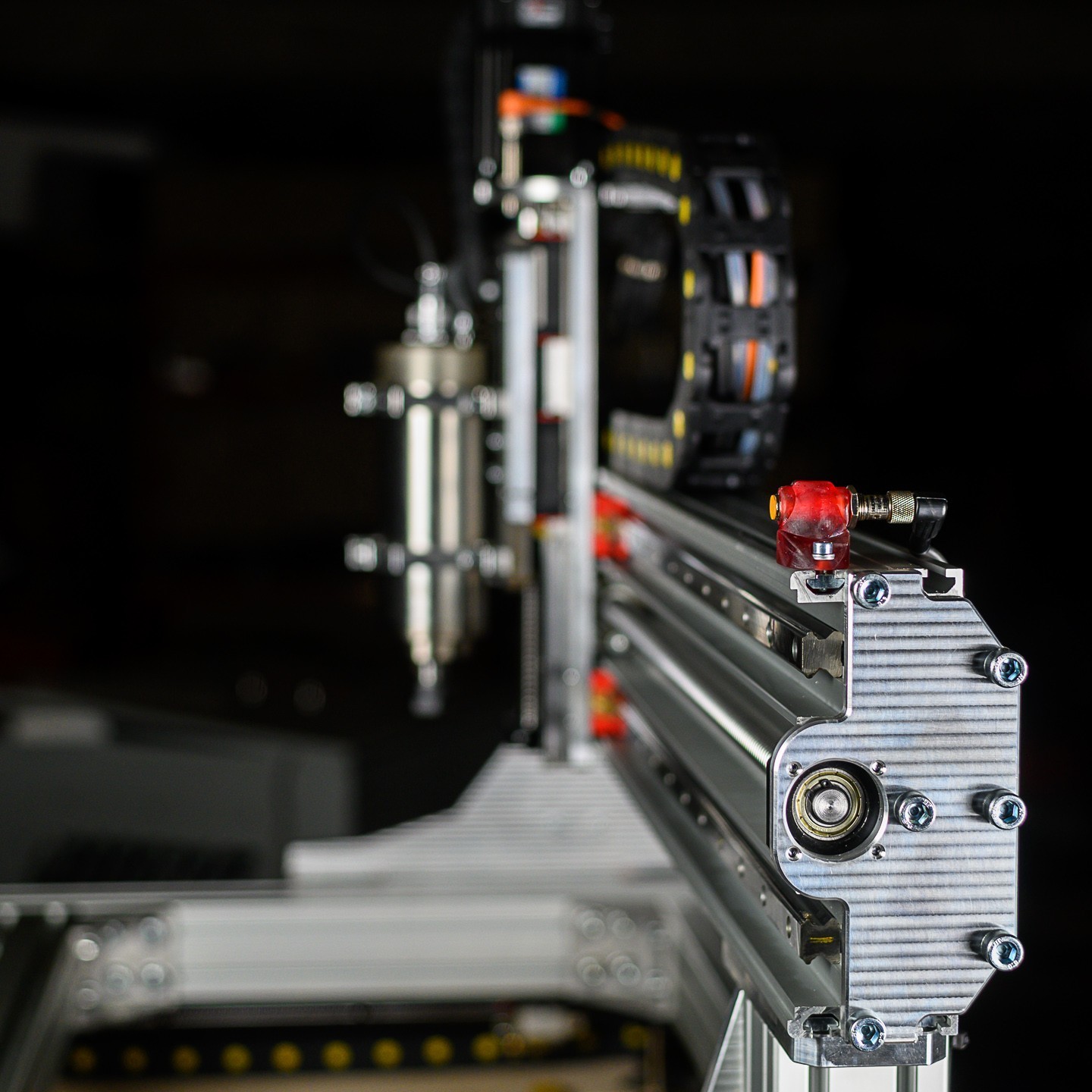

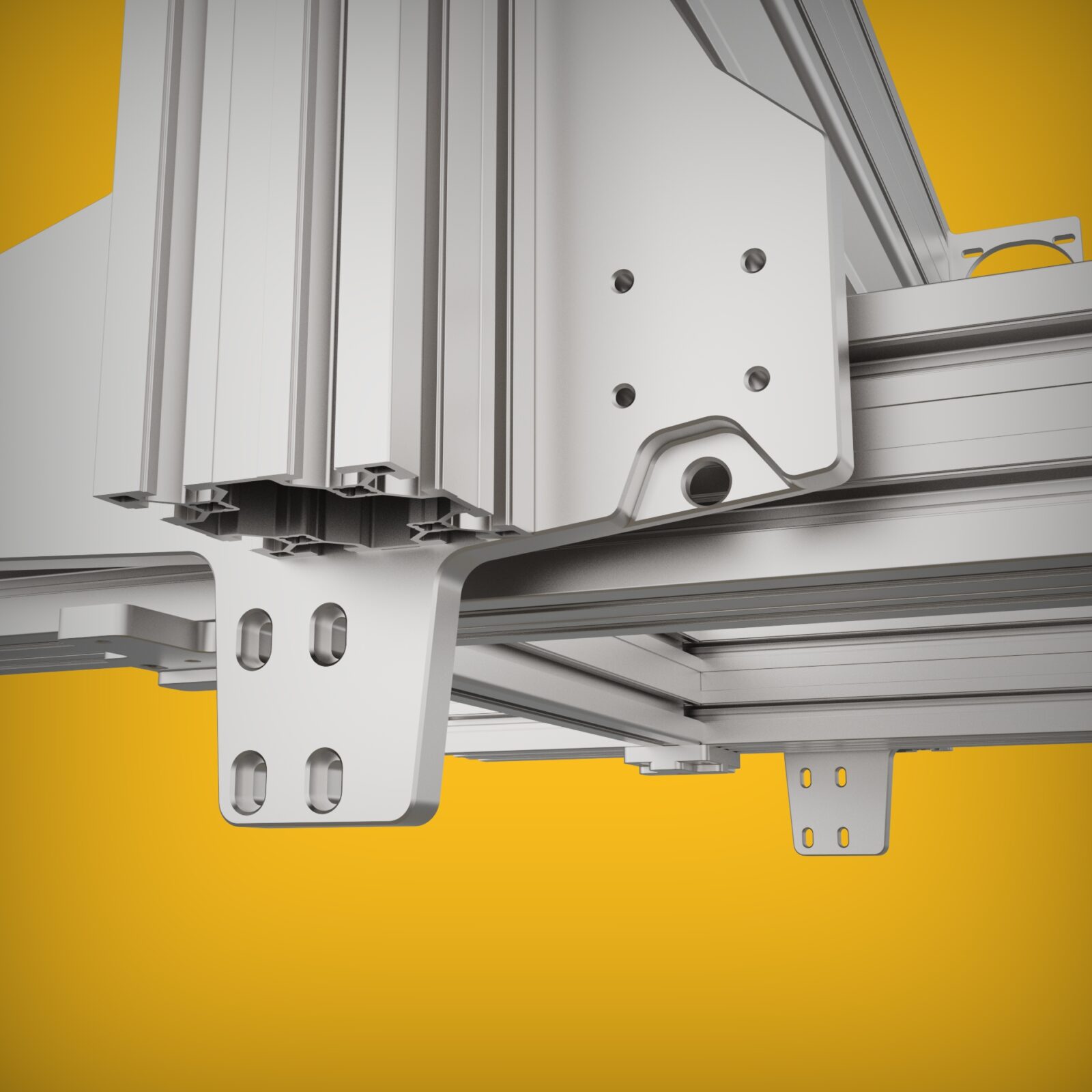

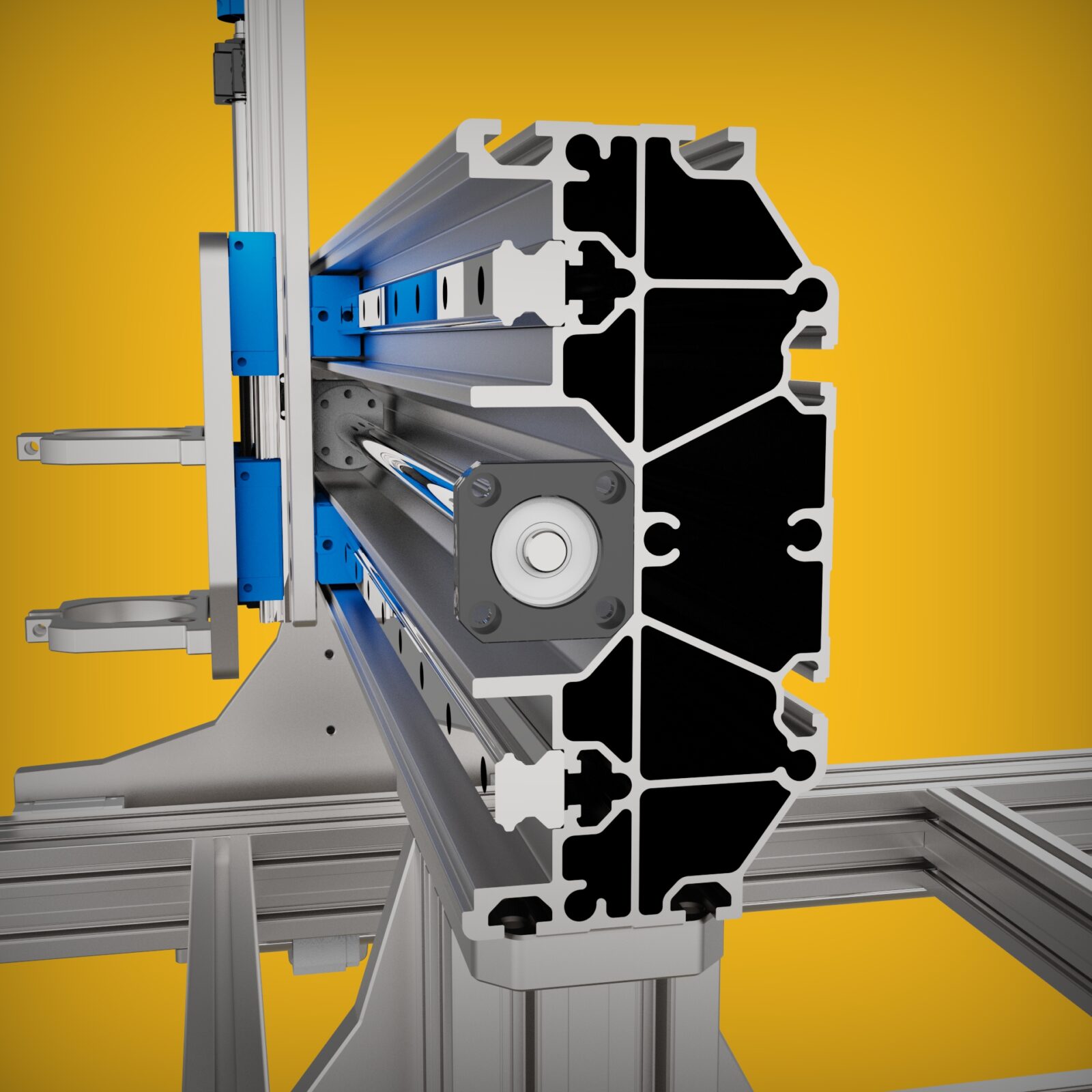

Linear Rails and Blocks:

The kit boasts 20 size rails for all axes, ensuring smooth, precise linear motion during operations. These durable and high-quality components ensure longevity and optimal performance.

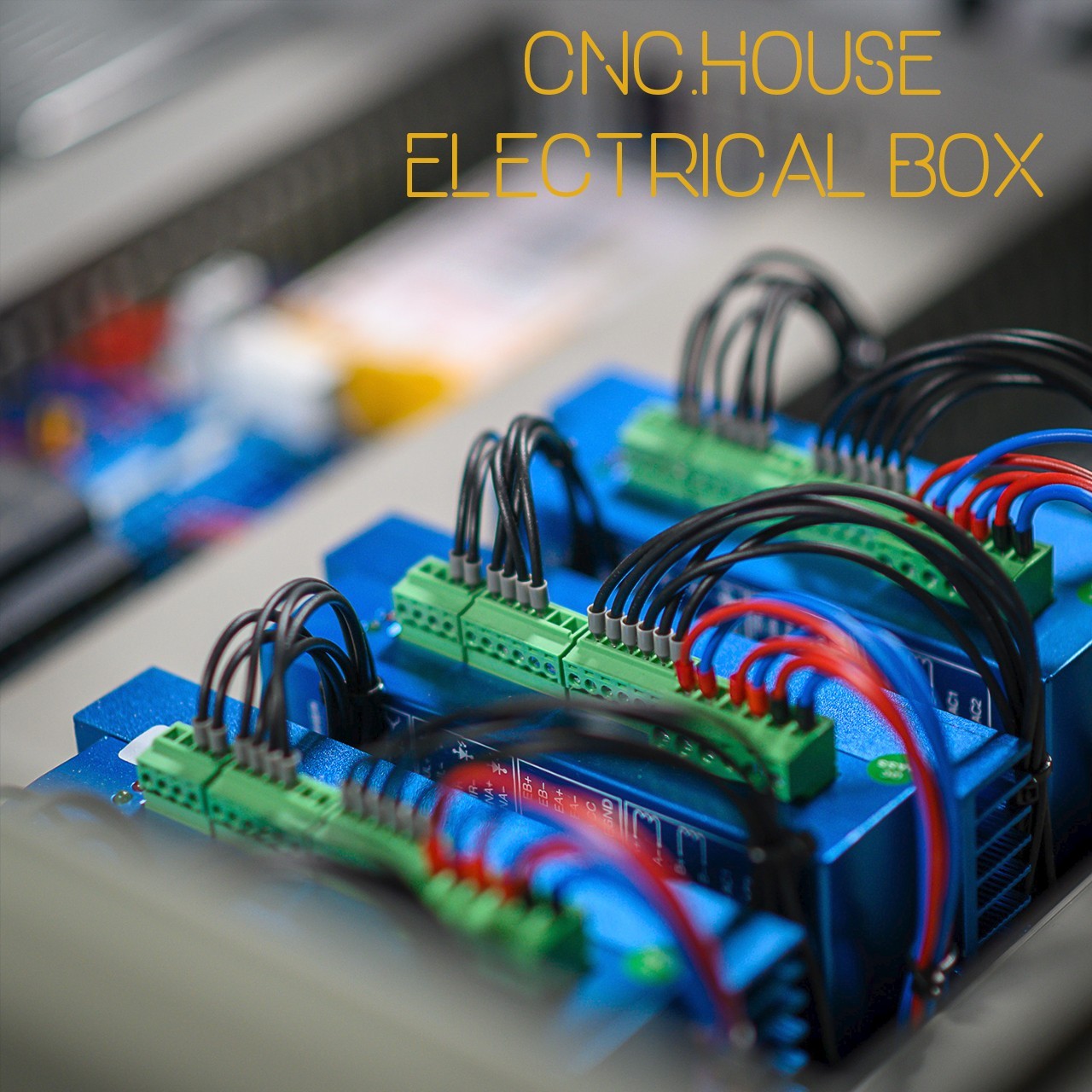

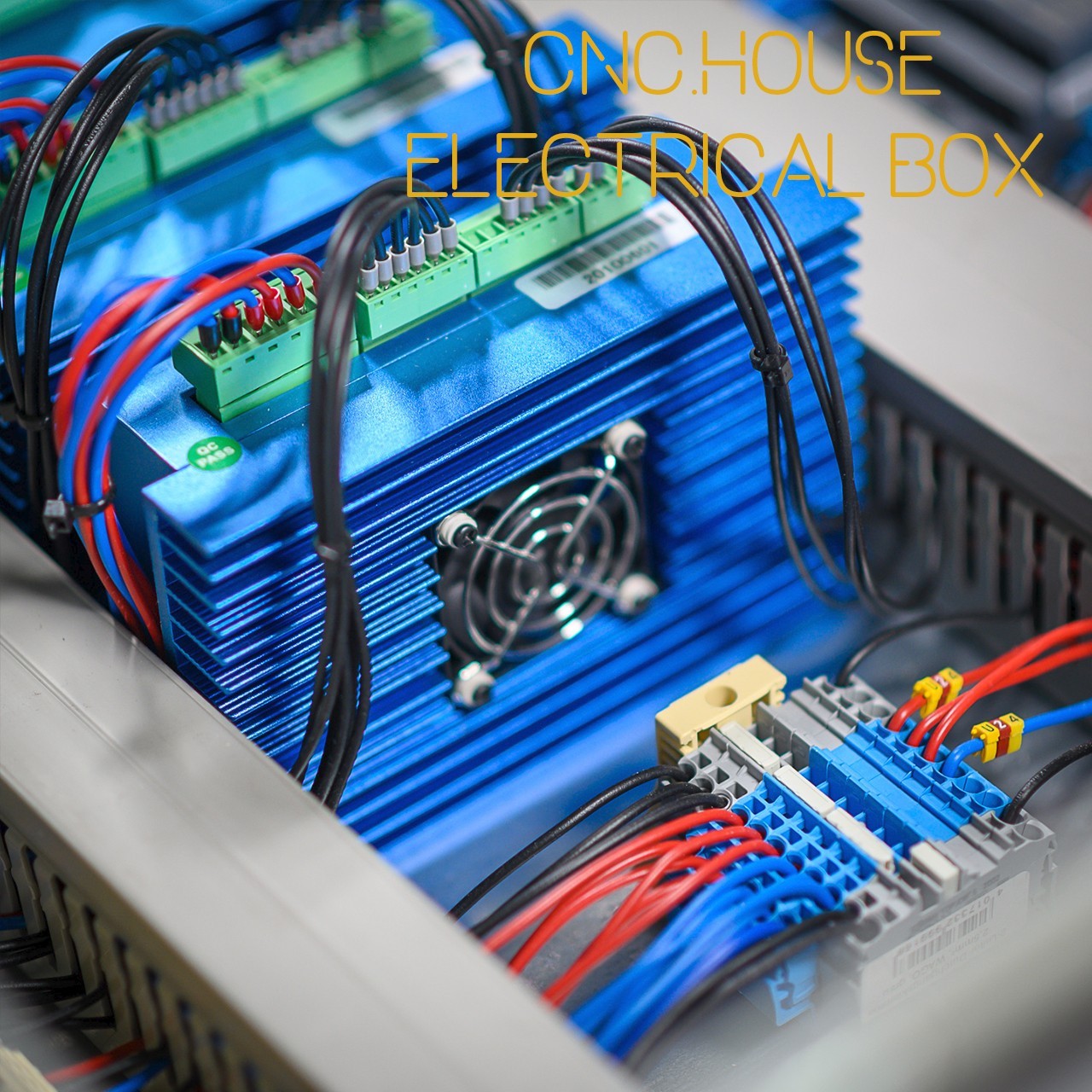

Stepper Motors:

Our kit now offers a selection between Nema 23 and Nema 34 stepper motors, enabling you to customize your kit according to your specific needs. Coupled with HBS57/HBS86 6A Hybrid Drivers, these motors provide superior motion and positioning control, essential for precision machining.

Y Axis Dual Motor System:

Unique to this model, a dual motor system on the long Y-axis allows superior geometric precision. This, combined with the UCCNC software, ensures consistently accurate perpendicular axis alignment, a critical factor in precision CNC machining.

X and Y Axis Ball Screws and Nuts:

This kit now includes 20-sized ball screws and nuts on the X and Y axes. These precision-engineered components provide low friction movement and exceptional positioning accuracy.

Energy Chains:

Included are energy chains for the X, and Y axes. These components protect and prolong the lifespan of moving cables in your CNC machine, mitigating the risk of cable wear or damage during operation.

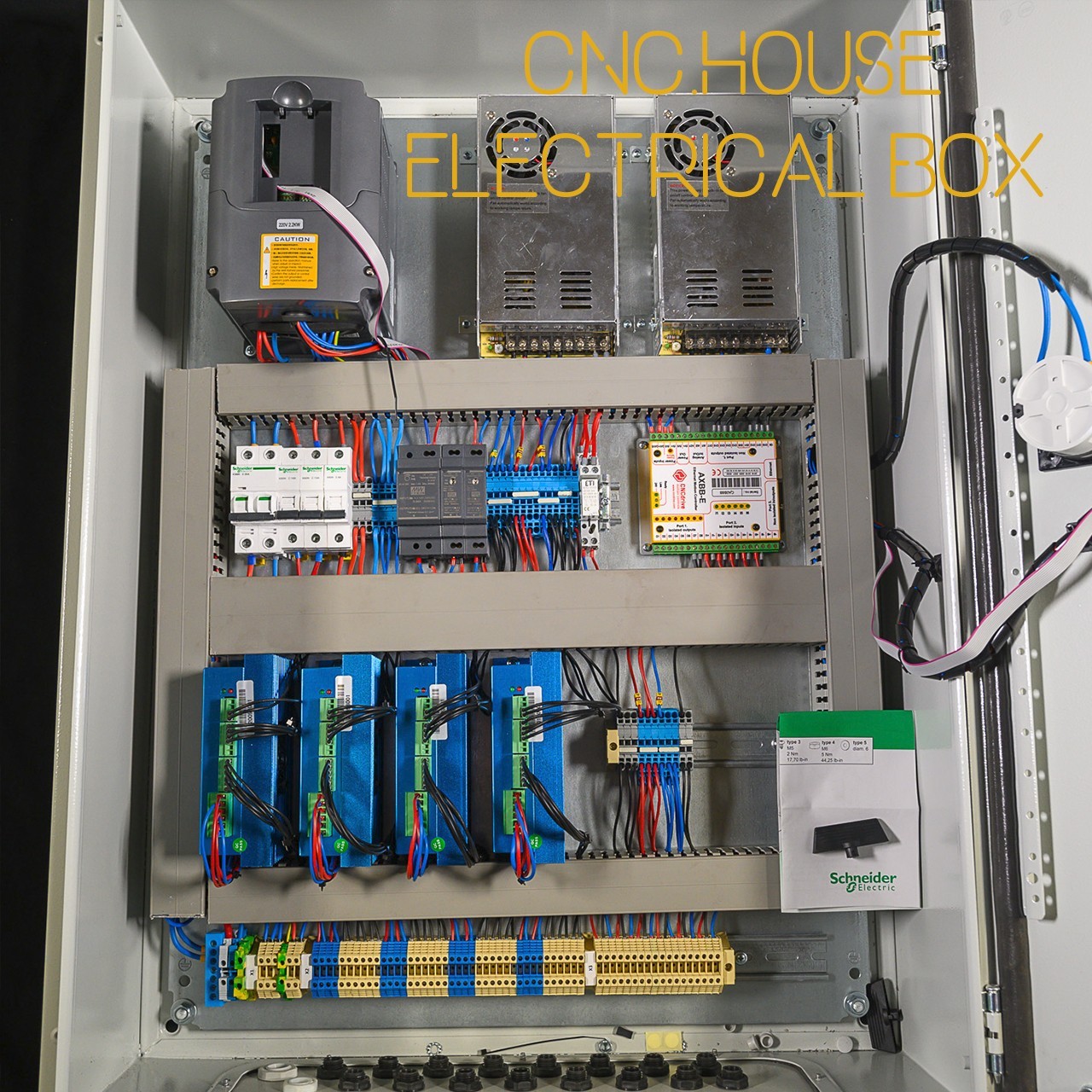

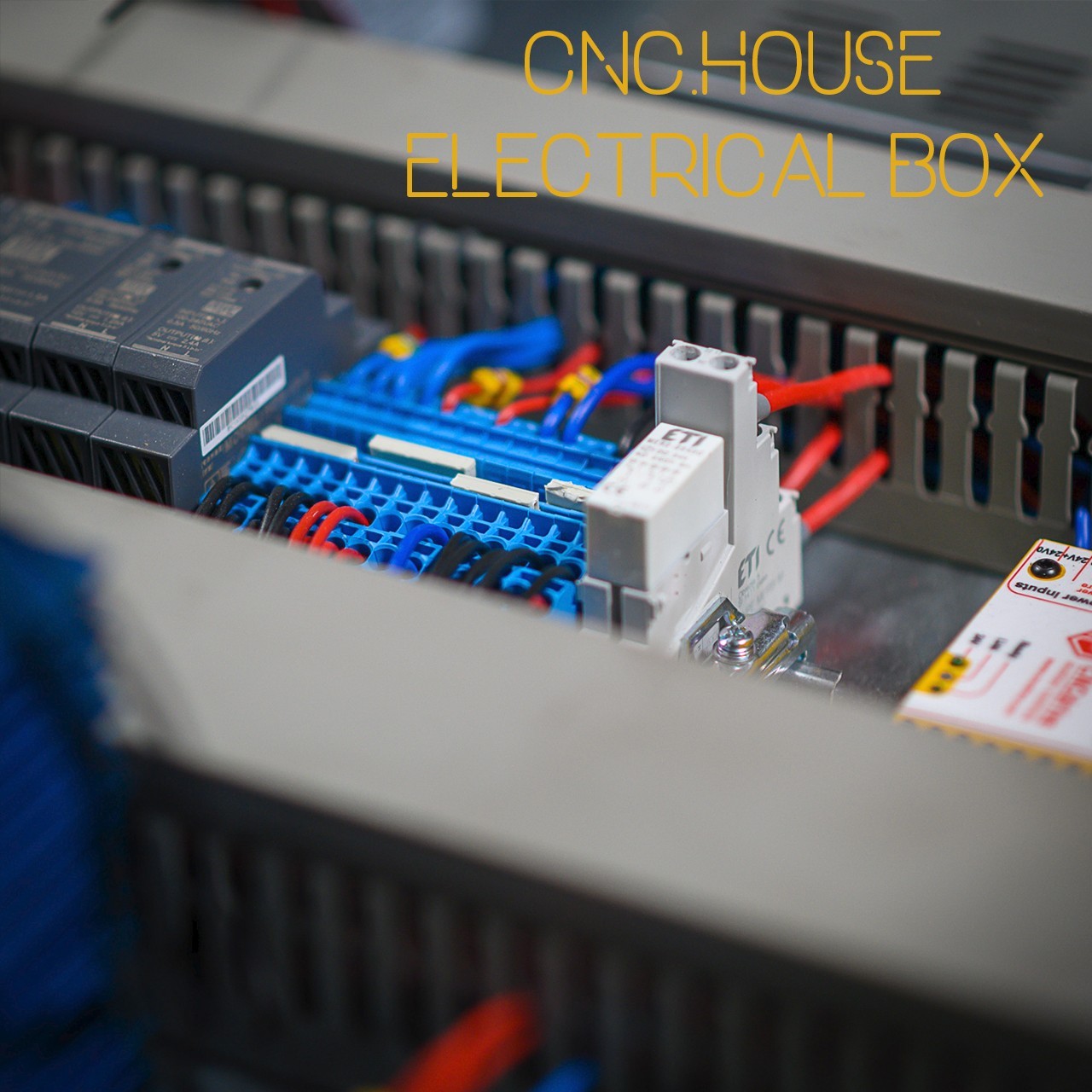

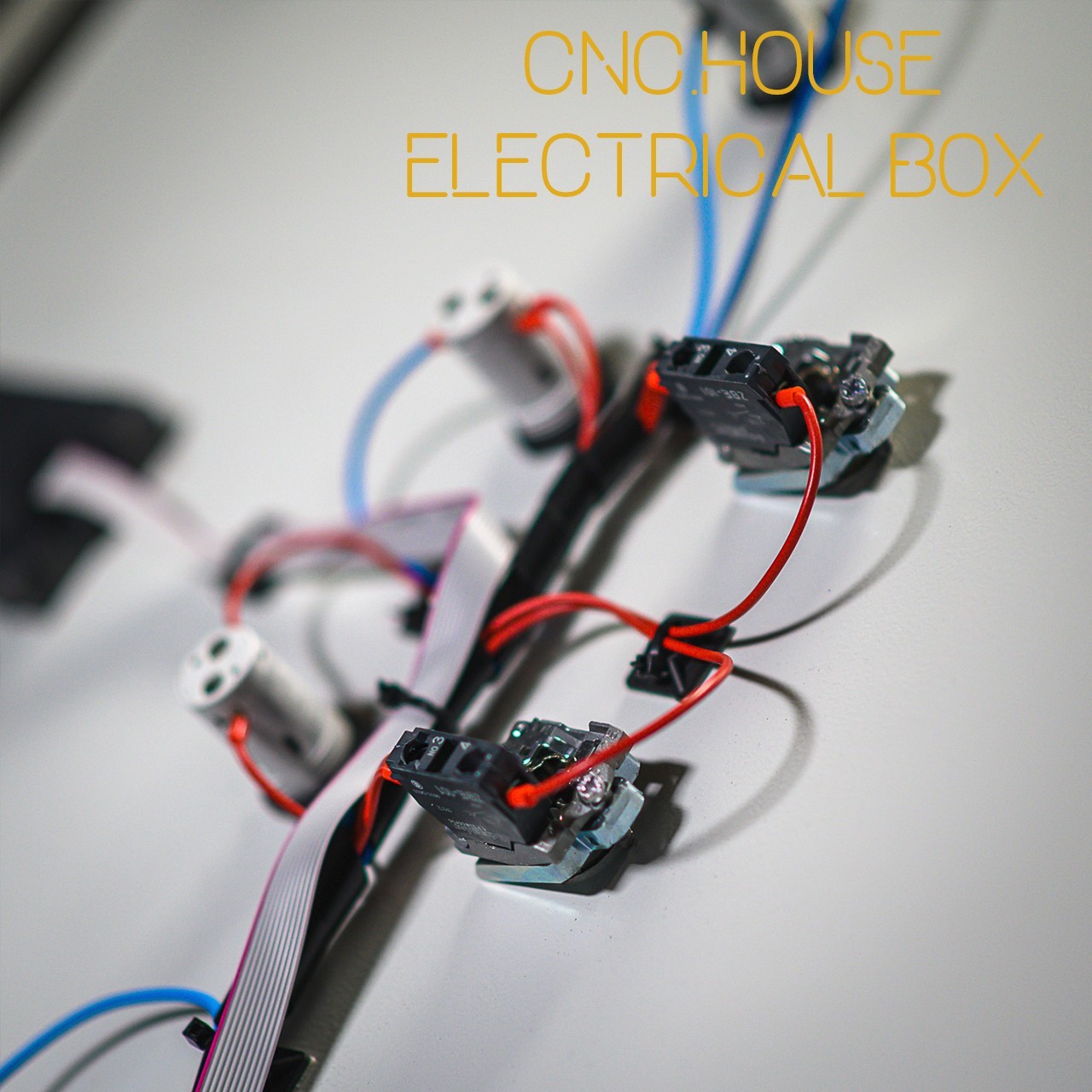

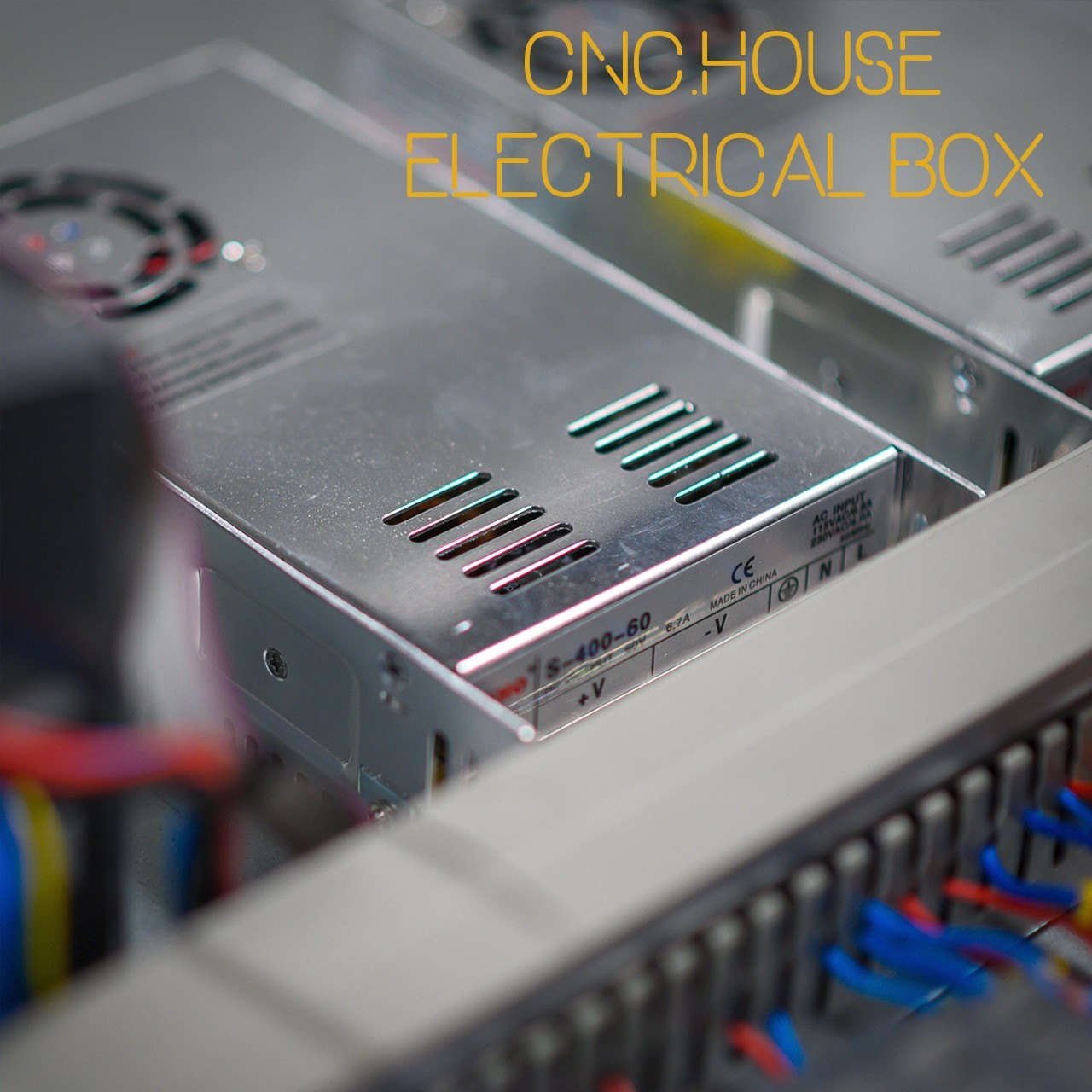

Electrical Cabinet:

A compact and organized electrical cabinet is included to safely house the machine’s electrical components.

Controller and Software:

The kit features an AXBB-E ethernet motion controller for seamless machine control. This controller is compatible with the user-friendly UCCNC software, a license for which is included in the kit.

Inductive Sensors:

Your kit will include three M12 inductive sensors, providing accurate detection of metal objects without physical contact, enhancing the safety and precision of your machine operations.

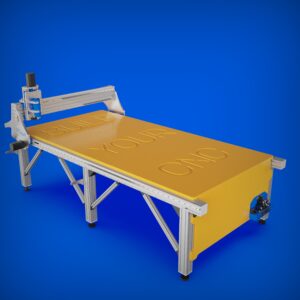

This Standard Line CNC Kit is designed to provide you with all the necessary components for a high-performance CNC machine. Guaranteeing precision, quality, and ease of use, this kit caters to both seasoned machinists and newcomers to the field, designed to exceed all your machining needs.

Optional Accessories – Edge Finders and Tool Length Sensors (TLS):

To further enhance the precision and versatility of your CNC operations, our kit can be supplemented with high-quality Edge Finders and Tool Length Sensors (TLS). These indispensable tools, manufactured in Europe to strict quality standards, ensure pinpoint accuracy in defining workpiece position and tool length within the machine’s workspace.

Edge Finders: These precision instruments are designed to accurately determine the edges of a workpiece. Our superior quality edge finders ensure precise positioning of your workpiece within the machine – a critical factor for achieving accurate machining results.

Tool Length Sensors (TLS): These high-grade sensors provide precise measurements of tool lengths, enabling the machine to adjust its operations based on the exact dimensions of the tools in use. Our high-precision TLS ensure optimal efficiency and accuracy in your machine’s operations.

Integrating these high-accuracy tools into your CNC kit will significantly elevate your machine’s performance and the quality of its output. With an impressive accuracy level of 0.01 mm, you can confidently take on even the most intricate and demanding projects, secure in the knowledge that your machine operates with supreme precision.

Detailed information:

Motors:

A stepper motor is another crucial component of your CNC. The stepper motor controls the precise movements of your CNC machine, and the choice of the motor affects the performance and accuracy of your operations.

Our CNC Kit offers robust stepper motor options, both designed for high performance and precision:

Nema 23 Closed Loop (Encoder); 6A 2.5N.m; HBS57 6A Hybrid Driver – This high-performance motor offers superior precision with a closed-loop control system, ensuring no loss of synchronization during operations. It features a hybrid driver, providing high torque at starting and low speed. It also maintains high stiffness at standstill, ensuring precision and stability during operations. The motor operates with a current of 6A, offering a torque of 2.5N.m, making it an excellent choice for most CNC applications.

Spindle Options:

When it comes to fine-tuning your CNC Kit with Closed Loop Stepper Motors and Ethernet Motion Controller – Standard Line, one of the most critical decisions you’ll make is selecting the right spindle. The spindle, the heart of your CNC machine, determines the range of tasks you can undertake and the precision of your results.

Our CNC Kit offers three distinct spindle options, each with its own strengths and perfectly suited for different types of projects:

- 1.5 kW Spindle – This middle-of-the-road option offers a balance of power and precision. It can handle more demanding tasks and a wider variety of materials, including hardwoods and light metals.

- 2.2 kW Spindle – The most powerful option available, this spindle is designed for heavy-duty work. It has no problem with tougher materials like steel and can maintain higher speeds for extended periods, allowing for faster project completion times.

All three spindle options come with air-cooling systems, ensuring optimal performance even during prolonged use. An efficient cooling system is crucial in maintaining the longevity of the spindle, preventing overheating and wear over time.

Take your time to consider the nature of your projects and the materials you’ll be working with when choosing your spindle. Your decision will significantly impact the overall effectiveness and productivity of your CNC machine.

Edge finders / Tool length sensors (TLS):

High-Quality Edge Finders / Tool Length Sensors (TLS):

In CNC machining, precision is everything. That’s why our CNC Kit includes high-quality Edge Finders and Tool Length Sensors (TLS) as part of the package.

These tools are essential for accurate machining operations. They allow you to determine the exact position of your workpiece and tool length within the machine’s workspace with a high degree of precision. This ensures that your machine operates accurately and produces precise, high-quality results.

Our edge finders and TLS are manufactured in Europe, adhering to stringent quality standards. They offer an impressive accuracy level of 0.01 mm, ensuring that your CNC machine operates with the utmost precision.

Edge Finders: These devices are used to locate the edges of a workpiece accurately. Our high-quality edge finders ensure that you can set your workpiece in the correct position within the machine, a critical factor in achieving accurate machining results.

Tool Length Sensors (TLS): Our top-of-the-line TLS provide precise measurements of tool lengths. This is vital in CNC machining, as it allows the machine to adjust its operations based on the exact dimensions of the tools in use. By using our high-precision TLS, you can ensure that your machine operates with maximum efficiency and accuracy.

Incorporating these high-precision devices into your CNC kit will significantly enhance your CNC machine’s performance and output quality. With the assurance of accuracy to the hundredth of a millimeter, you can confidently tackle even the most intricate and demanding projects.

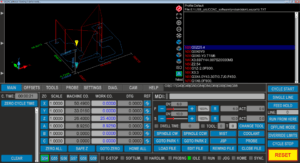

Controller and Software:

The AXBB-E ethernet motion controller and breakout board is a remarkable piece of technology that serves as the command center of your CNC Kit. It is a combined solution, offering both motion control and breakout board capabilities in one single, compact unit. This controller works seamlessly with popular software platforms such as UCCNC, Mach3, and Mach4.

Key Features of AXBB-E Ethernet Motion Controller and Breakout Board:

- Complete motion controller and breakout board solution in a single board.

- Multiple optically isolated and non-isolated outputs and inputs, providing various control capabilities.

- LED indicators on isolated I/Os.

- 24 Volts capable isolated I/Os.

- It can control machine tools with stepper or servo motor controls with step and direction interfaces.

- The controller can output a maximum of 400kHz stepping frequency and can work with up to 6-axes.

- Configurable I/Os, allowing for customization as per application requirements.

In terms of software capabilities, this controller can execute RS274 G and M codes and offers an unlimited number of user text macros with a flexible script engine. It provides real-time 3D toolpath viewing and supports OpenGL, ensuring fast screen update rates with low CPU/GPU usage. It also includes a built-in visual screen editor, allowing users to customize the screen fully.

The controller also supports parametric programming using internal variables and programming mathematical expressions. It includes a basic CAM module for DXF files import and offers Modbus TCP, RTU, and ASCII communication support via Modbus plugin. Moreover, it supports various plugins and functionalities, such as fast laser scan type engraving plugin, webcamera plugin, Xbox360 controller plugin, 3D printer plugin, and more.

This device is being continuously and actively developed and maintained, ensuring that it remains up-to-date with the latest technological advancements. It’s compatible with Windows XP, 7, 8, 8.1,10 on all both 32 and 64bit versions.

For more information on the AXBB-E Ethernet Motion Controller and Breakout Board, please visit the manufacturer’s website: https://www.cncdrive.com/

Please note that it is always recommended to consult with the manufacturer or a qualified professional when setting up your CNC kit to ensure that it is configured correctly for your specific needs.

UCR201 wireless CNC jog pendant:

Navigating your CNC machine operations with ease and precision is a must for any serious machinist. The UCR201 wireless CNC jog pendant is an exceptional device designed to enhance your control over the CNC machining process. This tool is compatible with UCCNC and Mach3 software, allowing for seamless integration with your existing setup.

Key Features of UCR201 Wireless CNC Jog Pendant:

- Wireless Connectivity: The UCR201 offers wireless control of your CNC machine, allowing for flexible operation without the constraints of wires. The pendant boasts an impressive transmit range of 10-15 meters, depending on the environment.

- Multi-Axis Control: This pendant supports up to 6-axis on-screen, giving you comprehensive control over your CNC machine.

- Large LCD Screen: The UCR201 features a large LCD screen with backlighting, allowing for easy reading of information even in low-light conditions.

- Industrial Wheel Encoder: This feature allows for precise, tactile control over your machine’s movements, increasing the accuracy of your operations.

- USB Wireless Transmitter: The pendant connects to your control PC via a USB wireless transmitter, providing a reliable and fast connection.

- Free Wireless Channel Frequency Operation: This feature ensures higher transmit range than wifi, ensuring a stable connection throughout your workspace.

- Function and Custom Pushbuttons: The UCR201 comes with function and custom pushbuttons, allowing you to customize your controls for a tailored machining experience.

- Enable Safety Buttons: Safety is paramount in any machining operation. The UCR201 features enable safety buttons on both sides of the pendant for easy access.

- Battery Operation: The UCR201 operates on batteries, offering long life and easy replacement when necessary.

The UCR201 wireless CNC jog pendant is a game-changer for CNC machining, offering precision control, ease of use, and flexibility. Its wireless design allows for smooth navigation around your workspace without the constraints of a wired connection, making it an excellent addition to your CNC Kit with Closed Loop Stepper Motors and Ethernet Motion Controller – Standadr Line.